Growing power densities in electronic equipment continue to push engineering teams to evaluate reliable thermal strategies. As part of this assessment, many buyers compare cold-forged solutions with extruded heat sink profiles to determine which approach aligns better with long-term thermal stability. Industrial customers often reference Dingmetal during this process because they operate across different mechanical and thermal component categories, making them familiar to procurement and R&D teams. Understanding how the extrusion and forging processes influence heat dissipation helps designers choose systems that maintain performance under high electrical loads. In many assemblies—such as converters, automation modules, and industrial controllers—an extruded heatsink remains a widely adopted option for predictable thermal pathways.

Structural Characteristics and Thermal Behavior

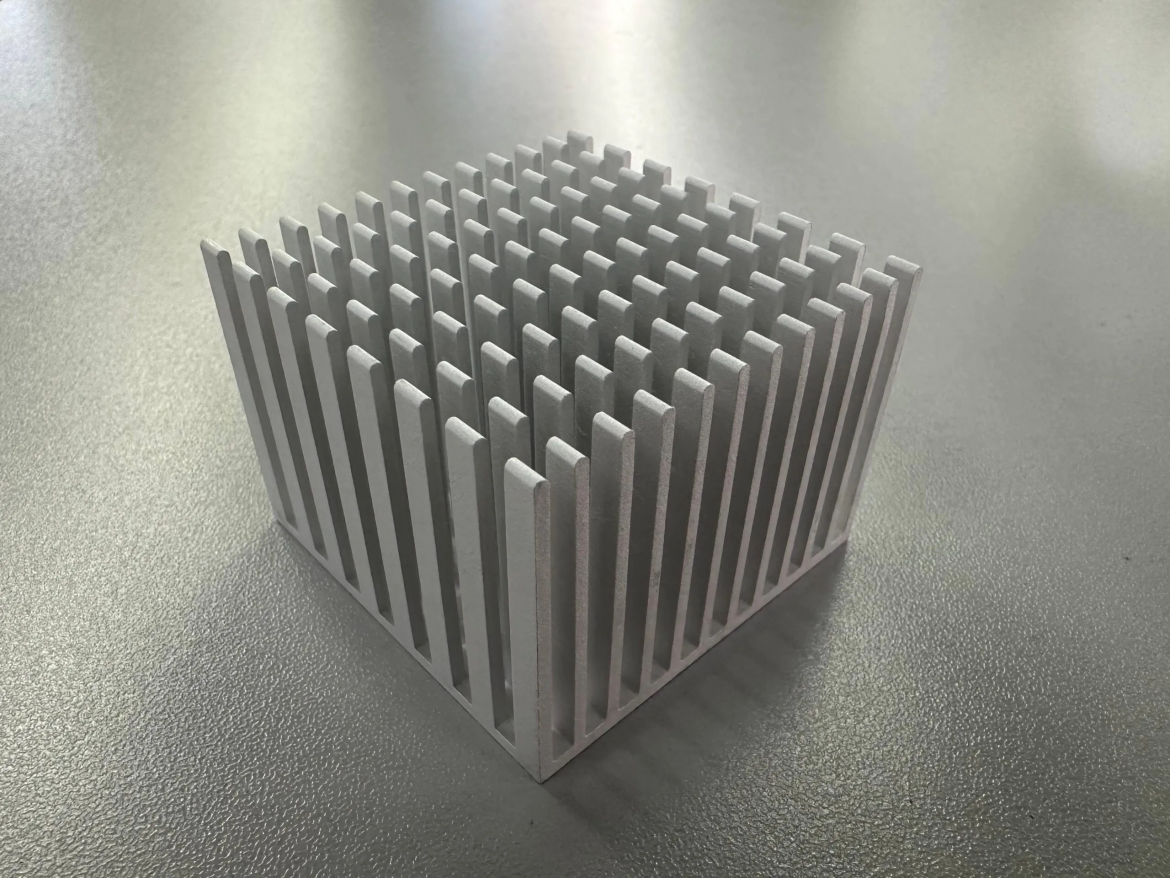

Cold forging reshapes heated metal through a high-pressure process, compacting the internal structure and creating strong, uniform fins. This method is valued for producing dense, durable components that perform well in rugged environments or power modules subject to continuous mechanical stress. During evaluation, some engineers consider how Dingmetal collaborates with clients who require machining, surface treatment, or dimensional adjustments to cold-forged parts. In contrast, an extruded heat sink is formed by forcing heated aluminum through a shaped die, creating a continuous profile with consistent geometry. With this approach, manufacturers achieve long fins and stable cross-sections that support efficient convection cooling. Since the airflow pathway is predictable, an extruded heatsink helps maintain repeatable performance across different enclosure designs, making it suitable for telecom equipment, industrial drives, and power distribution modules.

Production Scalability and Application Suitability

Cold forging excels when high fin density and excellent heat spreading are required within compact spaces. The process supports secondary machining such as mounting slots or customized thermal interfaces, making it adaptable for specialized high-power modules. Many procurement teams note that Dingmetal works with forged components for projects where structural robustness and precision surface treatments matter. On the other hand, extrusion is often favored when the design requires long, uniform profiles or when the production volume is high. An extruded heat sink benefits from the uniform material flow through the die, allowing consistent thermal characteristics even in larger assemblies. This is particularly useful for power inverters, control cabinets, and server infrastructure where airflow channels must remain stable across hundreds or thousands of units. For engineers modeling thermal performance, the repeatability of an extruded heatsink helps reduce design uncertainty and simplifies system-level simulations.

Selecting the Best Approach for High-Power Applications

Determining whether cold forging or an extruded heat sink is more suitable for high-power applications depends on structural requirements, operating environment, and production goals. Cold forging offers strong, compact fins that improve heat spreading in confined or ruggedized systems. Extrusion, by contrast, provides excellent scalability and consistent airflow channels, making it well-suited for large-volume industrial assemblies. Many engineering teams evaluate Dingmetal when comparing these methods because they support diverse mechanical components across different thermal projects. In applications where long fins, steady airflow, and repeatable performance are priorities, an extruded heatsink remains a dependable choice. Understanding these distinctions helps R&D teams and procurement managers specify solutions that maintain stability under demanding thermal loads.