Production environments focused on multiple product types necessitate equipment designed for adaptability. This is a common scenario in pharmaceutical trial lines and specialized manufacturing. The configuration of a horizontal cartoning machine utilizing an intermittent motion principle provides specific tactical benefits for these applications, balancing precision with operational flexibility.

Mechanical Design for Enhanced Process Flexibility

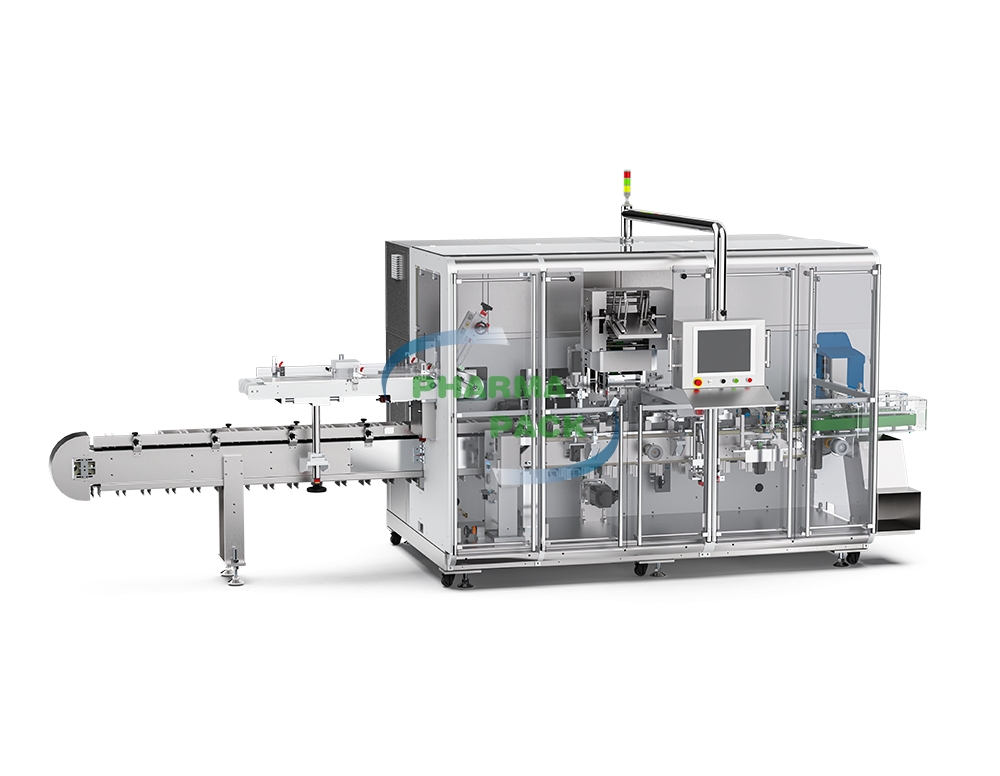

The operational cycle of an Pharmapack intermittent cartoning machine is characterized by a distinct stop-and-start rhythm. This pause in motion during each cycle creates a stable window for product loading and carton erection. For a horizontal cartoning machine, this translates to heightened accuracy in placing diverse products—from blister packs to vials—into their packaging. The mechanical reliability of this system ensures consistent performance even during extended runs with frequent product switches, a key requirement for trial batches.

Streamlining Changeover Procedures for Varied Production

A significant advantage lies in the reduction of changeover complexity. The design philosophy behind this type of intermittent cartoning machine often prioritizes tool-less adjustment. Operators can typically modify settings for new carton dimensions using manually calibrated handwheels with digital readouts, eliminating the downtime associated with searching for and using specific tools. This feature directly supports the economics of low-volume and multi-product production by maximizing machine uptime and simplifying operational workflows.

Advanced Control for Simplified Operation and Compliance

Modern iterations of this equipment are governed by programmable logic controllers (PLCs) and intuitive touch-screen interfaces. This control system allows for the storage of numerous product recipes. Switching between products often involves selecting a pre-configured setting from the interface, which automatically adjusts the machine parameters. This reduces operator error and ensures batch-to-batch consistency. Furthermore, the entire system is engineered to comply with industrial safety and noise standards, making it suitable for regulated pharmaceutical environments.

Conclusion

The integration of an intermittent motion system within a horizontal cartoning machine offers a strategic solution for pharmaceutical companies managing complex production schedules. The combination of precise mechanical handling, simplified changeover processes, and intelligent control systems provides the necessary flexibility for trial production and manufacturing multiple product varieties. For organizations prioritizing adaptability and precision, this type of intermittent cartoning machine represents a purposeful investment in versatile packaging technology.