Reverse engineering is a methodical way of taking apart a man-made object to learn about its design, how it was made, and what it was meant to do. In a nutshell, it goes backwards from the final product to the first blueprint. This idea has been around for hundreds of years, and it usually involved measuring and sketching by hand. But digital technology has completely changed the field. Today, 3D scanning for reverse engineering is the most common way to do reverse engineering. It replaces slow, error-prone manual measurement with fast, high-accuracy digital capture. This integrated methodology is essential in contemporary industry, encompassing the restoration of obsolete components to the execution of competitive analysis. Companies like 3DeVOK make the integrated metrology tools that make this change possible. These tools let engineers and designers accurately connect the real world with a digital model that can be changed and is smart.

The Old Necessity and the New Digital Change

In the past, reverse engineering was important for a number of reasons: to recreate designs for which original documentation was lost, to analyze competitor products to learn how they worked, or to adapt existing parts for a new use. The old way of doing things required very skilled technicians to use calipers, gauges, and CMMs (Coordinate Measuring Machines) to measure individual points and figure out complicated shapes. This method took a long time, was easy to make mistakes, and was almost impossible to accurately capture organic, free-form surfaces.

This workflow has been changed for good by the use of 3D scanning for reverse engineering. Non-contact scanners, like those that use structured light or lasers, can quickly capture the entire shape of an object’s surface, making a dense, very accurate 3D Scan Model. This digital transformation makes sure that the first step of the reverse engineering process is strong and dependable. The 3D Scan Model is the most accurate geometric template because it has millions of verifiable spatial coordinates that perfectly match the real world. This speed and accuracy are very important for professionals in all fields. They can skip weeks of manual work and go straight to the analysis and reconstruction phase.

Understanding Physical Geometry

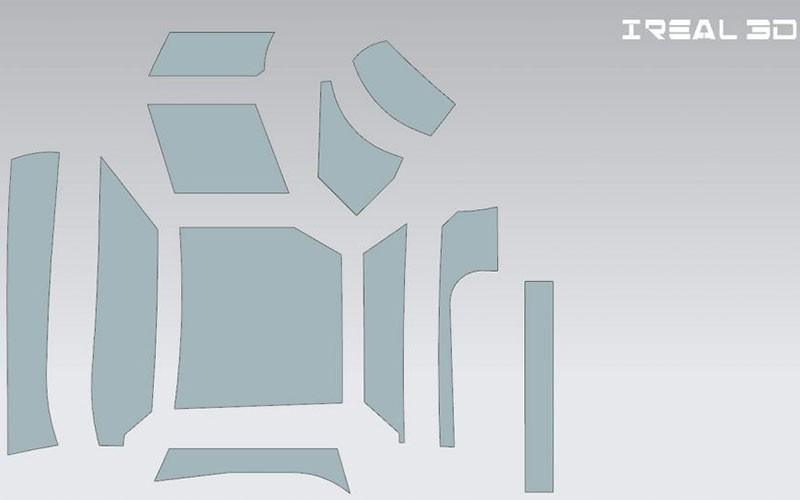

The core of contemporary reverse engineering involves transforming the static 3D Scan Model mesh into a dynamic, editable, parametric CAD model. This thinking process of interpretation is what 3D scanning reverse engineering is all about, and it needs special software. The goal is not just to make a copy of the original design, but to recreate the original design intent so that the digital model can be changed, simulated, and made.

The method uses a Hybrid Modeling approach. The engineer uses the software to do Feature Extraction for mechanical features like perfect planes, mounting holes, or cylinders. The software looks at the scanned data in that area and fits the most accurate mathematical primitive onto the mesh. It even figures out the exact size and shape that the original designer wanted, even if the object is worn. The technician uses the mesh as a guide to make high-quality NURBS surfaces for surfaces that are complicated, organic, or free-form, like ergonomic grips or aerodynamic curves. These surfaces smoothly follow the 3D Scan Model’s complex shapes, making a geometrically fluent representation. The technician can use both of these features to make a final CAD model that is both parametrically rigid where it needs to be and aesthetically fluid where it needs to be. This makes it the perfect digital twin for manufacturing.

The 3D Scanning Seal of Trust Reverse Engineering

No reverse engineering project is done until it has been thoroughly validated. 3D scanning technology makes this last step very quick and easy. After the editable CAD model has been rebuilt, it needs to be checked against the original scan data to make sure that the rebuilding is metrologically sound and meets all the necessary dimensional tolerances.

A deviation analysis is used to do this validation. The specialized software uses math to compare the reconstructed CAD surfaces to the original, high-density 3D Scan Model mesh. The result is a map that shows the size of the error or deviation across the whole part right away and in color. This ongoing, objective feedback loop lets the engineer make small changes until the digital model exactly matches the physical object within a guaranteed range of tolerance. This undeniable proof of accuracy, made possible by cutting-edge tools from a company like 3DeVOK, gives you the most confidence in the final output. The final editable CAD file (like STEP or IGES) is ready for all downstream manufacturing processes once it has been validated. This completes the powerful cycle of 3D scanning for reverse engineering, which turns an unknown physical part into a fully documented, production-ready digital asset.